Bevelling machines play a crucial role in diverse industries, facilitating the attainment of precise beveling and chamfering operations. The purchase of a bevelling machine necessitates a thorough examination to ensure the selection of an appropriate machine that aligns with one’s individual needs and requisites. This discourse aims to offer seven cardinal guidelines to enhance decision-making proficiency when procuring bevelling machines.

1.Determine Your Bevelling Needs:

When considering the acquisition of a bevelling machine, it is imperative to thoroughly assess one’s bevelling requirements. When contemplating the execution of a task, it is crucial to give due consideration to various aspects, including but not limited to the physical nature of the materials involved, the preferred bevel angles, the thickness of the materials, and the magnitude of work to be performed. This evaluation will facilitate the determination of the suitable specifications, features, and functionalities needed in the apparatus.

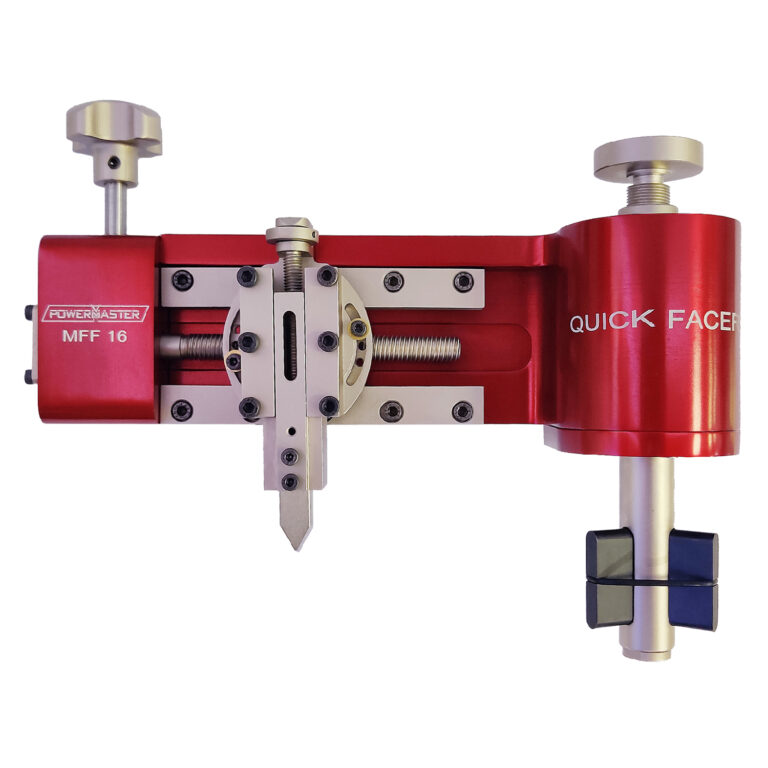

2. Assess Machine Quality and Durability:

Acquiring a bevelling machine of superior quality and durability is imperative to ensure sustained performance and dependability in the long run. One should search for machines produced by reputable brands that are renowned for their excellence in craftsmanship and meticulousness. It is advisable to assess the solidity of the construction, the dependability of the components, and the presence of warranties that guarantee the machine’s longevity and durability.

3. Consider Machine Automation and Efficiency:

The inclusion of automation features can greatly enhance the efficiency and productivity of your bevelling operations. Seek out machines equipped with automated feeding systems, versatile cutting speeds, and sophisticated control interfaces. These characteristics effectively simplify the beveling procedure, diminish the need for manual work, and boost overall efficiency.

4. Evaluate Cutting Accuracy and Precision:

The precise and accurate cutting ability of a bevelling machine is vital to obtain top-notch bevels. Seek out machines equipped with accurate cutting mechanisms, secure cutting heads, and meticulous adjustment controls. Furthermore, take into account attributes like the capability to automatically adjust the bevel angle and ensure uniform bevel dimensions across the entire workpiece.

5. Review Safety Features and Operator Comfort:

Ensuring safety is of utmost importance when using machinery. Make sure the bevelling machine you select is equipped with adequate safety measures such as emergency stop buttons, protective shields, and user-friendly controls. Operator comfort is enhanced and the likelihood of fatigue or injuries is reduced by the inclusion of ergonomic features like adjustable heights and comfortable grips.

6. Compare Prices and Consider After-Sales Support:

Although price is a significant consideration, it is advisable to prioritize the machine’s overall value and long-term advantages. Smartly analyze and evaluate prices, taking into account the quality, features, and support provided by various suppliers and manufacturers. Seek suppliers that offer thorough post-purchase assistance, encompassing instruction, upkeep, and easily accessible replacement pieces.

It is essential to carefully evaluate your specific requirements, the quality of the machine, its automation capabilities, precision in cutting, and safety features when purchasing bevelling machines. Conducting extensive research, evaluating different choices, and considering the machine’s long-term benefits will aid in choosing the ideal equipment that increases efficiency, provides precise outcomes, and prioritizes the safety of its operator. By heeding these crucial suggestions, you can make an educated buying choice and acquire a pipe beveling machine that fulfils your needs while aiding the effectiveness of your beveling activities.